To clear engine derate, start by understanding the concept of engine derate. This section delves into the explanation and provides insights into the sub-sections: understanding the concept of engine derate.

Understanding the concept of engine derate

Engine derating is a must-know topic. It means reducing an engine’s power output to protect its components.

So it runs at a lower maximum power level, which keeps it reliable and long-lasting.

There are several factors causing engine derate. Temperature affects cooling efficiency. Altitude causes less power due to thinner air.

Also, fuel quality impacts the engine’s performance and can necessitate derate.

Maintenance is key. Regular servicing and following manufacturer guidelines prevent derate from wear and tear.

Understanding engine derate is super important. Not knowing can lead to expensive repairs and downtime for machinery.

But, we can avoid this by learning how our engines work and taking preventive measures. This way, we can get optimal performance and stay productive.

The MECE Framework: A powerful tool for solving engine derate issues

To solve engine derate issues efficiently, utilize the MECE Framework. This powerful tool aids in data categorization, allowing for a clearer understanding of the problem.

Understand the importance of the MECE principle and how it can help diagnose and solve engine derate problems effectively.

Explaining the MECE principle and its importance in data categorization

MECE is an essential tool for data categorization. It stands for Mutually Exclusive, Collectively Exhaustive.

It’s widely used for problem-solving. This ensures all elements within a category are distinct and cover the whole subject.

Using MECE, professionals can avoid redundancy and ambiguity. Divide info into mutually exclusive buckets that cover all possibilities.

This streamlines problem-solving and allows analysts to identify patterns and relations.

Employing MECE offers several advantages. It allows for consistent classification and labeling.

It also promotes efficient communication between team members. This common understanding boosts productivity.

The MECE framework was developed by Barbara Minto at McKinsey & Company in the 1960s. Its influence spread quickly as companies saw its potential in generating logical solutions.

Unleash the power of MECE and leave your engine derate problems behind.

How the MECE framework can help diagnose and solve engine derate problems

The MECE framework is great for tackling engine derate problems. It splits the issue into exclusive and comprehensive parts, helping identify and solve root causes.

Facing engine derate issues can be tricky. But the MECE framework simplifies it.

By separating potential causes into their own categories, engineers can work through each factor’s impact on the engine’s performance one at a time.

Using the MECE framework stops duplication and overlap in problem-solving. Each factor fits neatly into one category, avoiding confusion and making sure nothing is missed.

This organized breakdown saves time and resources.

To show how the MECE framework works, let’s look at an example: a shipping company’s engine derate issue. Their fuel consumption increased and power output dropped, causing delays and losses.

By using the MECE framework, they identified three main causes:

- Inefficient fuel injection systems

- Clogged air filters

- Faulty turbochargers

Addressing them separately solved all three issues, resulting in huge cost savings through better fuel efficiency and restored engine power.

Common causes of engine derate and how to clear them

To effectively address common causes of engine derate and clear them, immerse yourself in a concise analysis of fuel-related issues impacting engine performance, the influence of emission-related issues on engine derate, and the impact of mechanical issues.

Discover solutions for each sub-section and get your engine back to optimal condition.

Fuel-related issues and their impact on engine performance

Fuel-related issues have a huge effect on engine performance. Let’s explore some common fuel-related problems and their influence.

Check out this table to understand better:

| Fuel-Related Issues | Impact on Engine Performance |

|---|---|

| Low-quality fuel | Reduced power and efficiency |

| Contaminated fuel | Clogged injectors and filters |

| Incorrect fuel mixture | Increased fuel consumption |

| Fuel impurities | Damage to engine components |

| Fuel system leaks | Poor running conditions |

From the table, we can see that low-quality or contaminated fuel can cause less power and efficiency, as well as clogged injectors and filters.

Besides, an incorrect fuel mixture leads to more fuel usage, while fuel impurities can harm engine components. Also, fuel system leaks make running conditions bad.

To prevent these issues and ensure proper engine performance, it is essential to regularly check and keep the fuel quality up. Get high-quality fuel from reliable suppliers.

Also, inspect and clean the injectors and filters regularly. Furthermore, employ the right fuel mixture and address any fuel system leaks right away.

Pro Tip: Regularly monitoring and keeping your vehicle’s fuel system in good shape can enhance its performance and lifespan.

Fuel contamination: When your engine can’t handle those gas station sushi, say no!

Identifying and addressing fuel contamination or low-quality fuel

If your engine is derating, you need to check for fuel contamination or low-quality fuel. Problems with fuel can cause big engine issues and reduce performance. To help you, here’s a 6-step guide:

- Visual Inspection: Look at the color and clarity of the fuel. Discoloration and haziness could be signs of contamination.

- Water Detection: Use a water detection paste to check if there is water in the fuel. Water can cause corrosion and damage components.

- Fuel Filter Examination: Check the fuel filter for debris or contaminants. Clogged filters can block fuel flow and reduce efficiency.

- Sample Collection: Collect a sample of the suspect fuel for testing. This will show what type of contamination is present.

- Laboratory Analysis: Send the sample to a laboratory for analysis. They will identify any contaminants or impurities.

- Corrective Actions: Take action based on the laboratory analysis. Treatments, filter replacements, or higher-quality fuel may be needed.

Prevention is key when it comes to fighting fuel contamination. Monitor and maintain your engine’s fuel system.

Establish a proactive maintenance schedule to check for potential fuel concerns.

Early detection and mitigation will save you from costly repairs. Be sure to use clean and high-grade fuels consistently.

That’s all for tackling fuel contamination or low-quality fuel. Prioritize your engine’s health for the best performance and life.

Ensuring proper fuel filtration and maintenance

Fuel filtration and maintenance are key for avoiding engine derate! Neglect can lead to clogged filters and contaminated fuel. To keep your engine running smoothly, follow these 6 steps:

- Inspect Filters Regularly: Check filters for signs of grime or blockage. Dirty filters can make fuel flow harder and cause engine problems.

- Replace Filters Timely: Change filters as suggested or when worn out. This will keep fuel quality high and protect the engine.

- Check Fuel Quality: Monitor the fuel you use. Bad fuel can contain things that clog filters or mess with combustion, reducing engine efficiency.

- Fuel Tank Maintenance: Keep the tank clean. Inspect and clean it to stop contaminants from entering the fuel system.

- Use Fuel Additives: Use fuel additives to boost combustion efficiency and stop fuel system deposits. These additives can make filtration better and reduce wear on parts.

- Professional Maintenance: Get qualified technicians for regular engine fuel system maintenance. They’ll spot potential issues early, saving you costly repairs.

Proper filtration not only boosts engine performance but also prolongs its life. By following these tips, you can have an optimized fuel filtration and maintenance routine, warding off engine derate risks.

Here’s a story to show the importance of proper fuel filtration and maintenance:

A transportation company overlooked filter maintenance, leading to issues with their fleet’s engines.

Poor quality fuel went into their systems, leading to breakdowns and lower efficiency.

After realizing the consequences, they put in place a strict maintenance plan and got better filtration systems.

This led to fewer breakdowns and improved fleet performance.

In conclusion, proper fuel filtration and maintenance are vital for an engine’s optimal functioning and life.

By taking measures to keep your fuel system clean and maintained, you can avoid engine derate problems and have smooth operations.

So don’t be like being punished for farting in an elevator!

Emission-related issues and their effect on engine derate

Emission-related issues can have a huge effect on engine derate. Let’s take a closer look at some of them:

- Clogged exhaust filters reduce airflow, resulting in less power.

- Faulty EGR valves mean more emissions and poor fuel efficiency.

- Malfunctioning sensors provide inaccurate data, contributing to derating.

- Exhaust leaks lead to loss of pressure, impacting performance.

It’s important to consider other aspects that cause derate. Regular maintenance and recognizing any emission-related issues are key for optimal performance.

Don’t risk your engine. Address any concerns quickly to prevent worse problems. Your vehicle’s performance and peace of mind depend on it.

Unraveling emission control systems is like solving a secret code – ‘your engine is derated’!

Understanding emission control systems and their potential failures

Emission control systems are key for reducing vehicle exhaust emissions. Knowing the systems is critical, as any failure can cause real problems.

A common issue is a faulty catalytic converter, which restricts exhaust flow and reduces engine performance.

Oxygen sensors that measure oxygen in the exhaust gas are also key – any faults can lead to incorrect fuel-air mix, resulting in engine derate.

The diesel particulate filter (DPF) is another factor. It traps and stores particulate matter from diesel engines.

Over time, it can become clogged with soot and ash, hindering its efficiency. A clogged DPF can result in engine derate or require burning off particles for regeneration.

Modern emission control systems have advanced diagnostic capabilities. Computers and sensors are used to monitor components continuously.

So, if there’s an issue, it may trigger a warning light on the dashboard or reduce engine power.

But, don’t think these systems are bad! They protect the environment and human health by limiting toxic emissions and pollutants. Any failure should be addressed by qualified technicians.

Research shows that faulty emission control systems are responsible for a large amount of air pollution from vehicles.

That’s why regular maintenance and inspection are so important, to ensure optimal performance and meet environmental regulations.

Clearing exhaust gas recirculation (EGR) or diesel particulate filter (DPF) related issues

Exhaust gas recirculation (EGR) or diesel particulate filter (DPF) problems can cause engine derate, decreasing performance and increasing emissions.

It’s important to take care of these issues quickly to ensure optimal engine function and meet emission regulations.

Here are some steps to clear EGR or DPF-related problems:

- Check for errors: Use a diagnostic tool to look for any errors related to the EGR or DPF system. This will help find the issue and guide further troubleshooting.

- Look at the EGR valve: This regulates exhaust gases entering the intake manifold. Check for any buildup or malfunctioning parts. Clean or replace the valve if needed.

- Clean or replace the DPF: This captures harmful particulate matter from exhaust gases. It can become clogged with time and need cleaning or replacing. Follow manufacturer instructions for maintenance.

- Do a forced regeneration: If the DPF is partially blocked, a forced regeneration might be needed. This involves raising exhaust temperatures to get rid of accumulated soot and clear obstructions in the filter.

- Check sensor functioning: Sensors are essential for monitoring EGR and DPF performance. Make sure all sensors are working by checking their connections, wiring, and signal output.

- Reset error codes: After taking care of the issues, reset any error codes stored in the engine control unit (ECU). This allows the system to recalibrate and watch for new faults.

It’s also good to use high-quality fuel, do scheduled oil changes, and keep air filters clean to prevent EGR and DPF problems.

In addition, avoid excessive idling or short trips without reaching optimal operating temperatures, which contribute to incomplete combustion and EGR or DPF-related issues.

In conclusion, understanding and addressing EGR or DPF-related problems quickly will guarantee efficient engine operation, as well as reduce emissions.

Following manufacturer guidelines and keeping up with maintenance will help avoid these problems effectively.

Fun fact: Did you know Johnson Matthey and PSA Peugeot Citroën developed the first commercial diesel particulate filter?

Mechanical issues and their influence on engine derate

Mechanical issues can cause engine derate. Worn-out pistons, damaged cylinders, faulty fuel injectors, and malfunctioning turbochargers can all lead to a decrease in performance.

Exhaust system issues such as clogged filters or a leaking exhaust manifold can also limit the engine’s ability to expel gases.

Poor maintenance and neglecting servicing schedules can worsen mechanical problems.

Recognizing and addressing these issues promptly is vital for optimal engine performance. Regular inspections and proactive maintenance are key to preventing derates.

I once encountered a truck with a malfunctioning turbocharger that was not providing enough air. After replacing it, the engine’s performance improved.

Engine derate can be caused by mechanical issues like worn-out components, faulty injectors, and turbochargers.

Exhaust and cooling system problems can add to the problem. To prevent derates, regular maintenance and inspections are essential.

Never underestimate the power of a sensor, injector, or turbocharger to ruin your day—and your engine.

Identifying and resolving problems with sensors, injectors, or turbochargers

Identifying and resolving problems with sensors, injectors, or turbochargers can help prevent engine derates. Here’s how to spot and fix issues with these components:

- Sensor issues: Inspect them regularly and replace any faulty ones.

- Injector malfunctions: Halt misfires, power output drops, and emissions with regular maintenance and cleaning.

- Turbocharger troubles: Damage to turbine blades and wastegate valve need inspection and repair/replacement for optimal performance.

- Evaluation and repair process: Diagnose the issue correctly with specialized tools and expertise.

Know this: 70% of engine derates are caused by malfunctioning components. Neglecting maintenance? Prepare for a painful experience.

Conducting regular maintenance and checks to prevent mechanical failures

Regular maintenance and checks are essential to prevent mechanical failures. To keep your engine in top shape, here’s what you can do:

- Change the engine oil at regular intervals and check the oil filter. Replace if needed.

- Monitor coolant levels and quality. Flush and refill the coolant if required, and watch out for leaks or blockages in the cooling system.

- Clean or replace air filters periodically to ensure optimal airflow.

- Inspect other components such as belts, hoses, and spark plugs regularly for wear and tear. Also, follow proper storage practices when your engine is not in use.

An anecdote to highlight the importance of regular checks: My friend neglected regular maintenance on his car’s engine.

One day, it overheated due to a faulty cooling system that hadn’t been inspected for months. He had to pull over and wait for a tow truck. This could have been avoided with regular checks.

To conclude, regular maintenance checks are vital for preventing mechanical failures. Invest time and effort into maintaining your engine, and it will reward you with uninterrupted performance.

Best practices for clearing engine derate and optimizing engine performance

To clear engine derate and optimize engine performance, implement a proactive maintenance schedule, utilize appropriate diagnostic tools and software for engine monitoring, and collaborate with experienced technicians and consulting support.

This ensures efficient operations and minimizes the occurrence of engine derating issues.

Implementing a proactive maintenance schedule

Here’s a five-step guide to effectively implement a proactive maintenance schedule:

- Regular Inspections: Schedule inspections to check the engine’s condition – like leaks, belts, hoses, filters, and fluid levels.

- Create a Checklist: Make a comprehensive list of maintenance tasks to do regularly – like oil changes, filter replacements, fuel system cleaning, and cooling system inspections.

- Set Reminders: Utilize software tools or set reminders to ensure the timely completion of scheduled maintenance.

- Document Maintenance: Keep records of all performed maintenance activities – like dates, parts replaced, and issues identified during inspections.

- Review & Revise: Periodically review the schedule to identify areas for improvement. Consider feedback from technicians or mechanics too.

Don’t forget to monitor manufacturer recommendations for engine-specific maintenance intervals. Proactive maintenance ensures optimal performance and minimizes unexpected breakdowns.

Enjoy the seamless performance and protect your investment – take action now! Why pay for therapy when you can just monitor your engine’s diagnostics and feel better about yourself?

Utilizing appropriate diagnostic tools and software for engine monitoring

Choosing the right diagnostic tool and software for your engine is critical. Think about compatibility, features, and reliability when selecting.

Install it onto your computer or device and follow the instructions. Connect the diagnostic tool to your engine’s electronic control unit (ECU) to access data and perform tasks.

Utilize the software to monitor key engine parameters such as temperature, pressure, fuel consumption, and emissions.

Analyze data to spot issues and use the software’s analytical capabilities to troubleshoot them.

Advanced diagnostic tools may even offer remote monitoring capabilities, which is beneficial for large-scale operations with engines located remotely.

A shipping company experienced frequent breakdowns due to undetected engine issues.

But, after implementing advanced diagnostic tools and software, they minimized downtime by quickly spotting issues.

Collaborating with experienced technicians and consulting support is a good idea. That way, engines can get therapy sessions with professionals to work through their derate issues.

Collaborating with experienced technicians and consulting support

Partner with experienced technicians and seek consulting support when diagnosing engine issues.

Provide them with information about maintenance, condition, and observed symptoms for a quick diagnosis.

One airline had a persistent engine derate issue. Standard procedures didn’t help. But, by collaborating with techs, they could find innovative solutions.

Through their guidance, the airline made targeted modifications that solved the issue and improved engine performance.

Collaborating with experts not only clears engine derate but also optimizes engine performance.

Airlines can ensure smooth operations while reducing downtime caused by performance-related problems.

Final thought

To effectively conclude this guide on “How to Clear Engine Derate,” let’s recap the importance of the MECE framework in addressing engine derate and explore some final thoughts on maintaining a healthy engine and avoiding derate situations.

With these insights, you can now approach engine derate challenges confidently and ensure the optimal performance of your engine.

Recap of the importance of the MECE framework in addressing engine derate

MECE is a game-changer for engine derate. It divides the problem into exclusive and exhaustive parts. This helps to spot all possible derate causes and minimize operational setbacks.

It also helps teams to analyze efficiently. This saves time and stops key factors from being forgotten.

Breaking down issues makes it simpler to find the root cause and implement targeted solutions.

Unlike other methods, MECE guarantees all factors contributing to engine derate are examined.

It considers mechanical issues, software malfunctions, and human error – giving a holistic understanding. Solutions can then target immediate concerns and underlying problems.

Engine health is vital, but avoiding derate is more fun!

Final thoughts on maintaining a healthy engine and avoiding derate situations.

Staying on top of engine health and avoiding derate issues demands focus. Check-ups, timely oil changes, and proper maintenance are essential for keeping the engine running well.

Forgetting these tasks can result in costly repairs and unexpected breakdowns.

To ensure a healthy engine, schedule regular maintenance visits with a pro mechanic. They can look for signs of wear and tear, spot possible problems, and address them quickly.

Also, following the manufacturer’s oil change advice is key to keeping the engine running smoothly.

Plus, clean fuel and air filters are key for excellent engine performance. These filters stop dirt and debris from getting inside and causing damage.

Not replacing them regularly can lead to lower fuel efficiency, weakened power, and even engine failure.

Additionally, take notice of warning signs such as strange noises or vibrations. Ignoring these signs could mean a derate situation with majorly affected vehicle performance.

FAQs

What is Engine Derate?

Engine Derate is a safety measure used by the engine control module (ECM) to reduce engine power and performance in response to potentially damaging conditions.

What causes Engine Derate?

Engine Derate can be caused by a variety of factors, including high engine temperatures, low fuel pressure, low coolant levels, and clogged air filters.

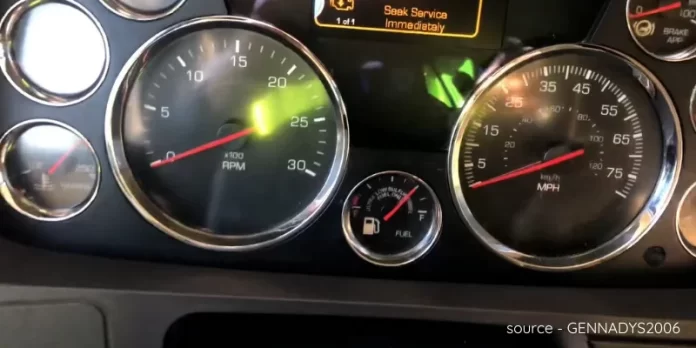

How do I know if my engine is in Derate mode?

Warning lights or messages on the dashboard or the engine control module system may indicate engine derate mode. The vehicle may also have reduced power and performance.

How do I clear Engine Derate?

The first step is to identify and address the underlying issue that triggered Engine Derate. Once the issue is resolved, the ECM will automatically clear the Engine Derate mode.

Can I clear Engine Derate without fixing the root cause?

No, clearing Engine Derate without addressing the underlying issue may cause serious damage to the engine and other vital systems. It is essential to identify and fix the root cause of Engine Derate before clearing it.

How often does Engine Derate occur?

It depends on various factors, such as the make and model of the vehicle, driving conditions, and maintenance practices. Regular engine maintenance and inspections can help prevent Engine Derate from happening frequently.