To measure gas struts, extend them and use a tape measure to measure the extended length.

Also, measure the rod length, which is the stroke length. Then, measure the diameter of the road and the barrel using a vernier.

Finally, identify and match the end fittings before purchasing the new struts.

But there’s more to know about how to measure gas struts. So, stick with us till the end.

Measuring Gas Struts: Step-by-Step Guide!

You’ll have to measure four dimensions and the material of your gas strut. So, how do you measure gas struts? First, you’ll need these tools:

- Vernier

- Tape measure

Now, follow the steps below:

Step 1 – Measure Extended Length

First, measure the extended length of your gas strut. Fully extend the gas strut from the end fitting center. You can also fully extend it by pulling with your hands.

Now, if your strut has end fittings, measure from the middle of one fitting to another.

If it doesn’t, measure from the end of the rod to the end of the tube.

Source: How to measure a gas spring

Measure this length using a tape measure.

Step 2 – Measure Stroke Length

Now, measure the stroke length. It refers to the rod length from the end of the fitting to the start of the tube. Back off the end fitting of the strut a couple of turns. This will give an accurate reading.

Step 3 – Measure Strut Size

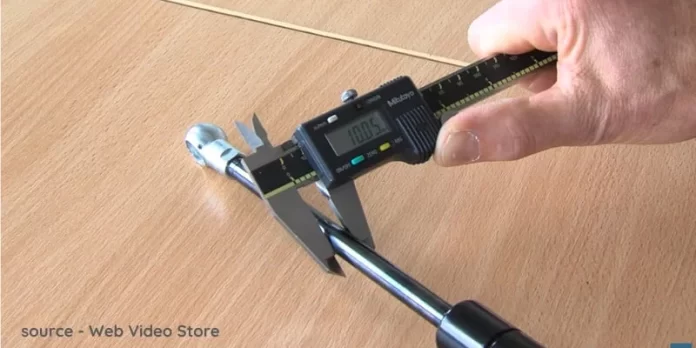

Next, you’ll have to measure the strut size. Do it by measuring the diameter of the barrel and the rod with a vernier.

It’s usually recorded in millimeters in rod/barrel format. For example, 6/15. 8/18, or 10/22. Usually, the bigger the diameter, the stronger the struts are.

Step 4 – Measure Force

Lastly, you’ll have to measure the force. Mostly, it’s written on the label or branding of the strut. It’ll be a number with Nm after it. For example, 450Nm.

If you can’t find the label, the weight of the object the strut holds has to be measured.

So, remove the gas strut and prop the object with a pole or scales. Here, 1kg= 10Nm. So, if the weight of the object is 45 kg, the force will be 45*10= 450 Nm.

Step 5 – Identify End-Fitting Material

After all the measurements, take note of what material the end fitting is. For example, plastic or metal.

And, in the case of Co-macs gas struts, measure the distance between the two ball joints’ centers.

Gas Struts Types: The Right Gas Strut For You

Now, there are six types of gas struts. Among them, you’ll have to find the one of your choice.

Type 1 – Standard Gas Struts

First of all, these are standard gas struts that have a sealed, constant pressure inside.

Type 2 – Side Valve Gas Struts

There are side valve gas struts that have a release side valve. It can release pressure quicker for faster operation.

Type 3 – Locking Gas Struts

Locking gas struts have a lever or remote button to lock in a position.

Type 4 – Friction Lock Gas Struts

Friction Lock gas struts lock onto a position using grip nuts.

Type 5 – Lock Open Gas Struts

The Lock Open Gas Strut automatically locks in position when it’s fully extended.

Type 6 – Protected Gas Struts

Protected gas struts have a protection cover to safeguard them from external factors. You can use any of these struts, depending on your needs.

Three Tips for Using Gas Struts

To ensure the proper function and longevity of your gas struts, follow these tips:

Tip 1: Ensure that the end fittings are completely screwed down to the gas springs. It’ll reduce the chance of the strut breaking off during application.

Tip 2: Don’t apply any solvents to the struts. It’ll wash off the lubricating oil from the piston rod.

Tip 3: Don’t paint the gas struts, as it can transfer to the main rod seal and damage it.

Also, be sure to mount your gas struts in pairs.

Can You Refill Gas Struts?

Yes, but you shouldn’t refill your gas struts. Generally, a gas strut has a lifespan of 8-10 years. After this, the pressure starts to fall.

But refilling the gas isn’t the right option. Just replace them with new ones. However, if you do refill them, don’t do it yourself. Contact a professional.

Bottom line!

Hopefully, now you know everything about how to measure gas struts.

Still, we have one last tip for you. Gas struts should be positioned 20% from the hinge. For example, for a 1000 mm drop, the hinge point should be 200mm. Thanks for reading the whole article.

Excellent write-up